KnowledgeECONOMICS

CONTACT US

Hunan Perfect Industry Co.,Ltd

Contact: Manager Hu, Manager Yi

Hotline:008618507312158

Cell phone:008613974960765

Address:Xiangyin County Industrial Park, Yueyang City, Hunan Province, China

Current location: HOME »Knowledge »vertical turbine pump

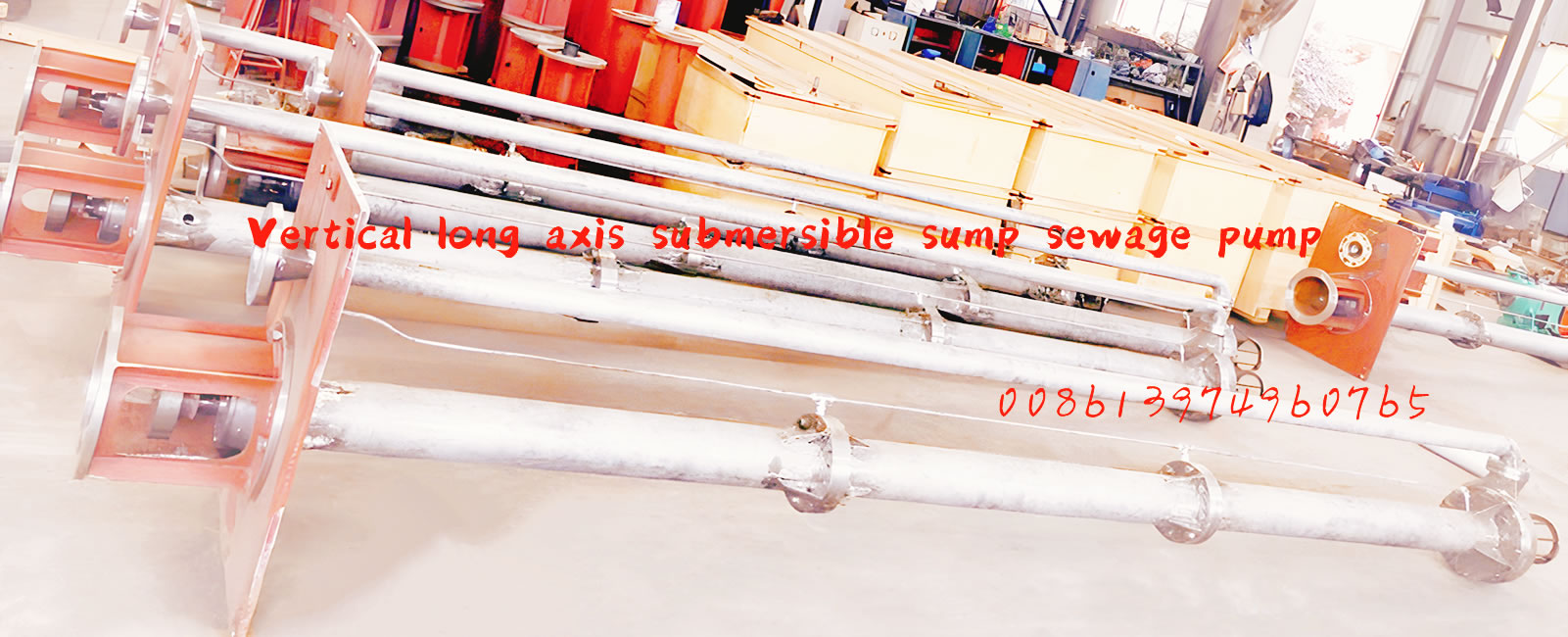

Starting of LC Vertical Long Axis Pump

(1) Close the outlet gate valve and pressure gauge cock, and connect the cooling and lubricating water of LC vertical long shaft pump.

(2) Check the flow rate and pressure of cooling and lubricating water. If the flow rate and pressure of cooling and lubricating water are not satisfied, the LC vertical long-axis pump is not allowed to start.

(3) Start the motor after the flow and pressure of the vertical long-axis pump meet the requirement and the water supply is more than 3 minutes. When the pump reaches the normal speed, open the pressure gauge cock, gradually open the gate valve in the outlet pipe, and adjust to the required working conditions. When the gate valve of the outlet pipe is closed, the continuous working time of the vertical long axis pump shall not exceed 2 minutes.

(4) If the vertical long shaft pump is sealed with packing, tighten the pressing nut on the packing cover evenly, so that the liquid leaks out in droplets, and pay attention to the temperature rise in the packing chamber.

Be careful: 1. In any case, the pump can not operate for a long time when the outlet gate valve is closed. Otherwise, it will cause pump vibration or even transport liquid vaporization, which may cause equipment damage and personal injury. 2. Packing cover should not be pressed too tightly. A small amount of leakage can lubricate the packing. Stopping leakage will cause packing burns and shaft bushing scratches. 3. When transporting sewage, guide bearings must pass cooling and lubricating water. The insufficient flow rate and pressure of cooling and lubricating water will seriously affect the service life of the pump. It takes more than 3 minutes to pass through the water before starting, and then turn off the cooling water after the pump stops turning completely. 4. When transporting clean water, the guide bearing can not pass cooling and lubricating water, but the protective pipe must be cancelled. |