KnowledgeECONOMICS

CONTACT US

Hunan Perfect Industry Co.,Ltd

Contact: Manager Hu, Manager Yi

Hotline:008618507312158

Cell phone:008613974960765

Address:Xiangyin County Industrial Park, Yueyang City, Hunan Province, China

Current location: HOME »Knowledge »vertical turbine pump

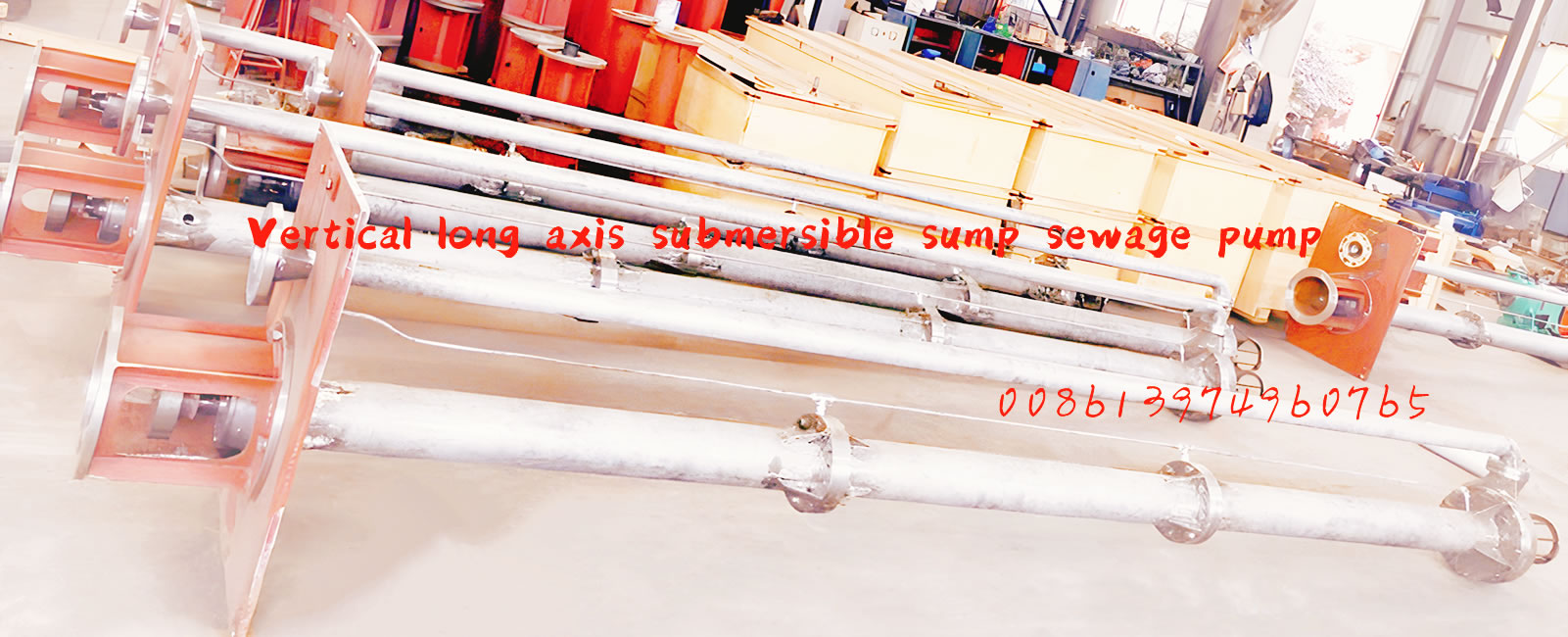

Operation of LC Vertical Long Shaft Pump

(1) Attention should be paid to the bearing temperature of LC type vertical long shaft pump not exceeding 35 C, and the maximum temperature not exceeding 75 C.

(2) In the process of driving and running, attention must be paid to the observation of instrument readings, bearing temperature, filler leakage and temperature, and pumps.

(3) Whether the vibration and noise are normal or not, if abnormal conditions are found, they should be dealt with in time.

(4) Check the flow rate and pressure of lubricating water regularly. No water cut-off is allowed in operation. Clean the filter screen regularly for the lubricating system with filter device.

(5) The normal leakage degree of packing chamber of LC vertical long axis pump is about 20-30 drops per minute.

(6) The lubricating oil level should be kept in normal position, not too high or too low, and should be replenished in time when it is too low. Generally speaking, after 300 hours of the first operation of the vertical long-axis pump, all new oil should be replaced, and then the new oil should be replaced regularly every 3000 hours of operation (users can also determine the oil change cycle according to the actual site and experience of the vertical long-axis pump).

Be careful:

1. It is not allowed to operate in the case of insufficient submergence depth of vertical long-axis pump, in order to avoid cavitation damage of vertical long-axis pump.

2. Continuous operation is not allowed when the vertical long-axis pump is less than 30% of the designed flow rate. If continuous operation is required under this condition, bypass pipes should be installed at the outlet and surplus flow should be connected to the inlet pipe of the vertical long-axis pump.

3. Continuous operation of vertical long-axis pumps is not allowed when the flow rate is 120% higher than the designed flow rate in order to avoid cavitation and motor overpower.

4. It is strictly forbidden to increase the rotational speed of vertical long-axis pumps. No liquid idling is allowed.

5. It is not allowed for vertical long-axis pump to operate for a long time when the outlet gate valve is closed. Otherwise, it will cause pump vibration and even transport liquid vaporization, which may cause equipment damage and personal injury.

6. In the operation of vertical long-axis pump, if abnormal sound or other faults are found, the machine should be stopped immediately for inspection.